Sampling Solutions

Sampling Solutions

Documentation outlining potential air sampling methods for a range of general applications and industries.

Documentation outlining potential air sampling methods for a range of general applications and industries.

There are many diverse applications for Gastec Gas Detection tubes. Some examples are shown below - hover or click the mouse over the image.

Used to test for chemicals before entering an area where an incident has occurred.

Checking for incomplete combustion of gas, and also for fumes given off from building materials.

Used as teaching aids, and in laboratory experiments, and to monitor air quality in teaching areas.

Monitoring for chemical hazards in, e.g. steelmaking, shipbuilding, automotive, pulp/paper production.

Monitoring for relevant chemical hazards during production processes, e.g. food and electronic products.

Monitoring of waste products from the energy process.

Monitoring for hazardous gases during excavation work, particularly for toxic gases.

Monitoring for contamination during laboratory experiments, or while manufacturing samples and prototypes.

Monitoring internal ventilation and external exhaust fumes, especially in workshop or servicing areas.

Monitoring of air quality and gases used during procedures in hospitals, clinics and veterinary surgeries.

Monitoring of air quality at workstations/desks, in conference rooms and in workrooms.

Monitoring of gases produced by cleaning agents for swimming pools.

Monitoring air quality in theatres, concert halls, hotels, etc.

Convenient and useful equipment-specific Step-by-Step Guides to Air Sampling procedures including the setting up of sample trains. They are ideal for becoming familiar with the use of the various types of air sampling equipment supplied by SKC.

In additional to our comprehensive catalogue we have brochures on a range of specific products, product manuals and instruction sheets, step by step guides and sampling methods. These can all be viewed online or downloaded for printing for future reference.

(Click on the image to download the glossary for reference)

Absorption

The penetration of airborne chemicals into a collection medium, such as impinger fluid, where the chemicals will dissolve or react chemically.

Active Sampling

The collection of airborne contaminants by means of a forced movement of air by a sample pump through appropriate collection media.

Adsorption

The collection of gases and vapours onto the surface of a collection medium such as the sorbent material in sorbent tubes.

Aerodynamic Diameter

A description of the shapes and densities of dust particles; the diameter of a unit-density sphere having the same settling velocity as the particle in question.

Aerosol

Microscopic liquid or solid particles dispersed into the air.

Air Volume

The total amount of air passed through a sampling medium; determined by multiplying flow rate in ml/min or L/min by the sample time in minutes.

Ambient Air

Air that is external to buildings and accessible to the general public.

ASTM

ASTM International is an international standards organization that develops and publishes voluntary consensus technical standards for a wide range of materials, products, systems, and services. They publish many air sampling methods.

Bioaerosols

Airborne particles, molecules, or volatile compounds ranging in size from 100 microns to 0.01 microns that are living, contain living organisms, or were released from living organisms.

Blank Sample

A representative sampling medium sent as a control with the actual sample to a laboratory. Blanks are subjected to the same procedures as samples, except no air is drawn through them.

Ceiling Value

The concentration that should not be exceeded during any part of the working day.

Chronic Obstructive Pulmonary Disease (COPD)

A group of lung conditions (diseases) that make it difficult to empty the air out of the lungs. Heavy exposure to certain dusts at work, chemicals and indoor or outdoor air pollution can contribute to COPD. For more information about preventing work-related lung diseases see the HSE website.

Closed-face Sampling

Filter sampling using a two or three-piece cassette with the cassette inlet section in place and the sealing plugs removed.

Constant Flow

A feature available on air sample pumps that allows the pump to automatically compensate for flow restrictions and variations, ensuring the flow rate is held constant throughout the sampling period.

50% Cut-point

Describes the performance of cyclones and other particle size-selective devices. For personal sampling, the 50% cut-point is the size of the dust that the device collects with 50% efficiency.

Cyclone

A sampling device used to collect and separate respirable particulate mass. The cyclone functions as a centrifuge; the rapid circulation of air separates particles according to size.

A sampling device used to collect and separate respirable particulate mass. The cyclone functions as a centrifuge; the rapid circulation of air separates particles according to size.

Dust

Solid particles rendered airborne during the crushing or grinding of hard, rock-like materials.

Filter

The medium which captures the solid particulate. It can be manufactured from many different materials, such as paper and cellulose.

Filter Cassette

An assembly that holds the filter medium (and filter support if required).

Fugitive Emissions

Emissions which could not reasonably pass through a stack, chimney, vent, or other functionally equivalent opening.

Fume

Solid airborne particles formed by the vapourisation of solid materials, oxidation of the vapour, and condensation of the oxide.

Gas

A substance that is in a gaseous state at normal temperature (25°C) and pressure (1 atm).

Gas Chromatography (GC)

Chemical analysis method for separating chemicals in a complex sample.

Grab Sampling

The direct collection of an air-contaminant mixture into a device such as a sample bag or detector tube over a brief period.

Gravimetric Analysis

Sample analysis of filters by determining sample weight.

Grit Pot

Fitted to the bottom of a Cyclone it captures larger unwanted particles.

HAVS

Hand-arm vibration syndrome (HAVS) is caused by occupational exposure to vibrating hand tools.

Hazardous Area

Any place in which an explosive atmosphere (containing flammable liquids, gases or vapours or combustible dusts) may occur in quantities such as to require special precautions to protect the safety of workers.

High Flow Sampling

The collection of airborne contaminants (typically particulates) at flow rates greater than 1000 ml/min.

Indoor Environmental Quality

The impacts of the indoor environment, including but not limited to air quality, lighting, and thermal comfort, on occupant health, comfort, and performance.

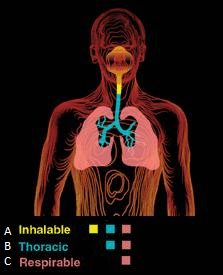

Inhalable Particulate Mass

Particulate Mass (100 μm 50% cutpoint), hazardous when deposited anywhere in the respiratory tract.

Integrated Sampling

The collection of air contaminants over an extended period.

Intrinsic Safety

A protection technique for safe operation of electrical equipment in hazardous areas by limiting the energy, electrical and thermal, available for ignition.

Low Flow Sampling

The sampling of airborne contaminants (typically gases and vapours) at flow rates less than 500 ml/min.

Matched-weight Filters

Two filters that match in weight; the top filter collects contaminants, the bottom filter serves as a control. After sampling, both filters are weighed and the difference between the weights is the sample weight.

Media or Sampling Media

The medium onto/into which the contaminant is collected, e.g filter material, the sorbent material in sorbent tubes or a sample bag.

Mist

Droplets rendered airborne by rubbing, boiling, splashing, or otherwise agitating a liquid.

mg/m3

1 mg/m3 is a measure, equivalent to one teaspoon of flour, spread over a football field to a height of one metre.

Nanoparticle

Intentionally manufactured particles with at least one dimension in the range of 1 to 100 nanometers (nm).

NIOSH

The National Institute for Occupational Safety and Health is the United States federal agency responsible for conducting research and making recommendations for the prevention of work-related injury and illness. They publish many air sampling methods.

Open-face Sampling

Filter sampling using a three-piece cassette with the cassette inlet section removed - typically used for sampling asbestos and other fibres.

OSHA

The Occupational Safety and Health Administration is an agency of the United States Department of Labour. OSHA's mission is to assure safe and healthful working conditions for workers. They publish many air sampling methods.

PAH

Polycyclic Aromatic Hydrocarbon

Particulate Matter (PM)

A mix of solid particles and liquid droplets suspended in air. Origin, shape, size, and composition vary. Standards exist for PM10 (diameter ≤10 μm) and PM2.5 (diameter ≤2.5 μm) because they are easily trapped in the lungs and are most likely to cause adverse health effects. Additional particles of concern are PM1.0 (diameter ≤1 μm) and PM Coarse (diameter <10 μm and >2.5 μm).

Parts per Million (ppm)

1ppm is about the same as the contents of a party balloon in the volume of 50 three bedroom houses.

Passive (Diffusive) Samplers

Small air samplers or “badges” that collect airborne gases or vapours without the use of a pump. Chemicals diffuse through a diffusion barrier onto a sorbing medium inside the sampler at a fixed rate that can be scientifically determined.

Small air samplers or “badges” that collect airborne gases or vapours without the use of a pump. Chemicals diffuse through a diffusion barrier onto a sorbing medium inside the sampler at a fixed rate that can be scientifically determined.

PCB

Polychlorinated biphenyl

Pore Size Rating

Filter pore size ratings are based on liquid filtration ratings. Filters will retain much smaller particles from air (e.g. a 0.8 µm liquid rated filter will retain >50% of particles as small as 0.08 µm).

A nominal or approximate rating is usually applied to depth filters. Unlike membrane filters, depth filters do not contain a uniformly defined pore structure, but rather fibres or sintered particles that intertwine to create a torturous path of openings that allow air to pass through, but trap particles throughout the depth of the filter. Because of this structure, depth filters are usually tested for pore size by passing liquid containing particles of a certain size through the filter. If the filter traps an acceptable amount of the specific-sized particles (despite the openings in the filter being larger that the test particles), that particle size becomes the "liquid nominal" pore size rating for the filter. Nominal pore size ratings are typically stated as "Filter removes >xx% of particles ≥ µm".

Preloaded Filter Cassettes

Ready-to-use cassettes that comprise a cassette, filter, support pad, and sealing plugs.

Preweighed Filters

Individual filters that are weighed to within 5 decimal places before they are loaded into a cassette.

Primary Standard

An instrument that bases measurements on direct, measurable linear dimensions, such as the length and diameter of a cylinder that will not change over time or be altered by temperature or atmospheric pressure. Examples of primary standards are bubble flowmeters.

Respirable Crystalline Silica (RCS)

Silica is a natural substance found in most rocks, sand and clay and in products such as bricks and concrete. In the workplace these materials create dust when they are cut, sanded down etc. Some of this dust may be fine enough to reach deep inside the lung, this is known as respirable crystalline silica (RCS) and can cause harm to health. Significant exposure to RCS can cause silicosis and lung cancer.

Respirable Particulate Mass

Particulate Mass (4 μm 50% cut-point), hazardous when deposited in the gas exchange regions of the lungs.

Sampling Parameters — Rate, Time, and Volume

Consult specific methods to determine the range given for each parameter. In the SKC Sampling Guide under “Sampling,” some chemicals have two different recommendations for sampling rates and times; the sampling rate for an 8 hour sample is listed with the shorter period rate in parentheses. The choice of rate is dependent on sampling requirements.

Sampling or Sample Train

The entire sampling system: sampling medium (sorbent tube, filter, cyclone, IOM, etc.) connected to a sample pump with flexible tubing.

The entire sampling system: sampling medium (sorbent tube, filter, cyclone, IOM, etc.) connected to a sample pump with flexible tubing.

Secondary Standard

Devices, such as rotameters, that base their calibration upon primary standards and may be affected by temperature, atmospheric changes, and mishandling. Secondary standards require periodic re-calibration to a primary standard.

Short-term Exposure Limit (STEL)

A 15 minute time-weighted average exposure that should not be exceeded during any part of the working day.

Smoke

Particles resulting from the incomplete combustion of organic matter and consisting predominantly of carbons and oxides of carbon.

Solvent Desorption

The process of extracting adsorbed chemicals from sorbent material through the use of solvents.

Source Emissions

Particulate or gaseous emissions generated from a stationary source, such as a stack.

Thermal Desorption

The process of extracting adsorbed chemicals from sorbent material through the use of heat.

Thoracic Particulate Mass

Particulate Mass (10 μm 50% cut-point), hazardous when deposited anywhere in the lung airways and the gas exchange regions.

Transmission Electron Microscopy (TEM)

Analysis method, which yields information on the internal structure of materials.

TLV-TWA

An ACGIH-defined concentration level in air, typically for inhalation or skin exposure, to which it is believed a worker can be exposed day after day (8 hours per day, 40 hours per work week) for a working lifetime without adverse health effects.

8 hour Time-weighted Average (TWA)

The average full-shift exposure level calculated by weighting concentrations throughout a workday with respect to time. The denominator “eight hours” is used because OSHA standards are based on an 8 hour working day. OSHA, ACGIH and HSE use the following formula to calculate TWA:

TWA = C1xT1 + C2xT2 + C3xT3 ... CnxTn

8 hrs

TWA = Time-weighted average concentrations in ppm or mg/m3

C = Concentration of contaminant during an incremental exposure time

T = Time — incremental exposure time

Ultrafine Particulate Matter

Ultrafine particles are less than 100 nanometers (0.1 μm) and the result of combustion, friction, or natural processes in the air or water. While nano-sized, ultrafine particles are not nanoparticles because they are neither intentionally manufactured nor of a constant composition or size.

Vapour

The gaseous form of a substance that is typically a liquid at normal temperature (25°C) and pressure (1 atm).

Vapour Intrusion

Volatile chemicals in buried wastes and/or contaminated groundwater emit vapours that migrate through subsurface soils into indoor air spaces of overlying buildings.

Workplace Exposure Guidelines

The concept of size-selective sampling of industrial aerosol is based on the measurement of particles that are associated with a specific human health effect, i.e. how deeply particles penetrate into the respiratory tract. ACGIH recommends that particle size-selective threshold limit values (TLVs) be expressed in three forms:

Workplace Exposure Monitoring

Measuring the workplace exposure to show that the control of exposure to hazardous substances (chemicals, dust) is adequate.